Yongxiang Hydraulic is a cylinder factory with has 16-year experience .These custom tie rod cylinders often require precise engineering designs. Hydrostatic testing is needed to ensure performance and safety after assembling.

YX01LG W 01 140L - CA 250 B 140 R 2000 - 02 A B F

| Symbol | Implication |

| YX01LG | Yongxiang Hydraulic Tie-Rod Hydraulic Cylinder |

| W | Double Piston Cylinder (No such symbol for single piston cylinder) |

| 01 | Design No. 01 |

| 140L | Pressure Level: 70L, 140L |

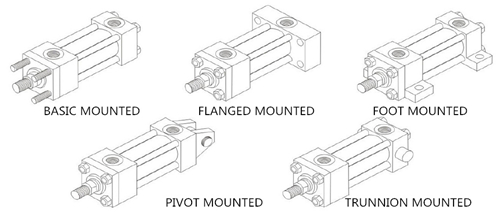

| CA | Installation Type: SD, LA, LB, FA, FB, FY, FZ, FC, CA, CB, TA, TC |

| 250 | Rod Dia: 32, 40, 50, 63, 80, 100, 125, 140, 150, 160, 180, 200, 220, 250 |

| B | Piston Dia Type: B, C |

| 140 | Rated Pressure: 7, 14MPa |

| R | Buffer Position: B: Both Ends R: Rod Head H: Rod End N: No Buffer |

| 2000 | Stroke (mm) |

| 02 | Oil Port Thread: 01- Inch 02 - Metric |

| A | Oil Port Position Thread: A, B, C, D |

| B | Cushion & Exhaust Valve Position: A, B, C, D |

| F | Dust Cover |

| Rated Pressure MPa | 7 | 14 | Min Startup Pressure | 0.3MPa | ||||

| Big Cavity | Rod Cavity | Big Cavity | Rod Cavity | Working Temp | -5℃-+80℃ | |||

| B | C | B | C | Max Allowed Speed | 400mm/s | |||

| Max Allowed Pressure MPa | 9 | 13.5 | 11 | 18 | 18 | 14 | Efficiency | >90% |

| Fluid: Mineral Oil, Water-glycol Fluid, Phosphate-Easter Fluid, High Water Based Fluid | ||||||||

Produsction and Inspection Process

Produsction and Inspection Process  Company Certificates

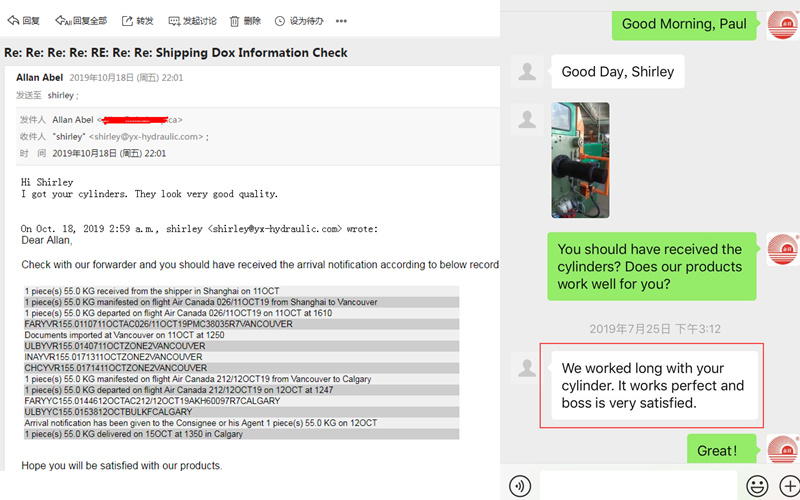

Company Certificates  Customer Comments

Customer Comments  FAQ: Q1: Are you a trading company or manufacturer? A1: We are the manufacturer with Exporting License. Q2: How long have you been in the Hydraulic Cylinder industry? A2: Since 2005 Q3: How long is your warranty period? A3: 12 months after on board. Q4: How long does it take to process customized orders? A4: It usually takes 30-45 days to process. It can be discussed. Q5: Have you been exported overseas? A5: We have been exporting to the USA, Canada, Japan, Russia, etc. If possible, when contact with us, please apply information as below

FAQ: Q1: Are you a trading company or manufacturer? A1: We are the manufacturer with Exporting License. Q2: How long have you been in the Hydraulic Cylinder industry? A2: Since 2005 Q3: How long is your warranty period? A3: 12 months after on board. Q4: How long does it take to process customized orders? A4: It usually takes 30-45 days to process. It can be discussed. Q5: Have you been exported overseas? A5: We have been exporting to the USA, Canada, Japan, Russia, etc. If possible, when contact with us, please apply information as below | Bore | Rod | Stroke | Work Pressure | Mounting | Work environment |