- Steel smelting

- Rolling equipment

- Steel rolling machinery

- Rolling machine

- Blast furnace for sheet metal

- Cutting

| Symbol | Implication |

| YC08YCD | Yongxiang Hydraulic YCD: Differential Cylinder YCG: Synchronous Cylinder |

| 250 | 250 Series: Rated Pressure 25MPa 350 Series: Rated Pressure 35MPa |

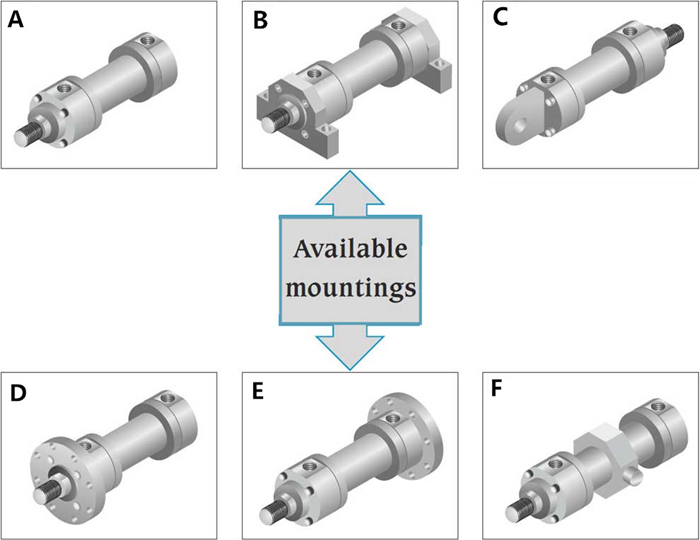

| B | Installation Type Symbol: A, B, C, D, E, F |

| 100/70 | Rod Dia / Piston Dia mm |

| 100 | Stroke (mm) |

| A | Rod Ends Connection Type: A: Thread Connection B:4* Rod End: Welded Connection Rod Head: Screwing |

| 10 | Series No. |

| 01 | 01: BSP Thread 02:ISO Thread |

| C | C: CK45, Hard Chrome Plating H: 3* CK53 Quench and Hard Chrome Plating N: CK45 Chemical Nickel Plating & Hard Chrome Plating |

| A | G: 2* Thread of CGA, CGAK Spherical Hinge Earring CSA Bushing Earring A: 2* CGAS Spherical Hinge Earring |

| D | Buffer Type: U: No Buffer K: Two End S:Rod Head K: Rod End |

| M | M: Mineral Oil –NBR Oil Seal V: Phosphate Ester – PVDF- HFP Oil Seal |

| A | Piston Seal: A: U Type Oil Seal V: V Type Oil Seal T:1* Slip Ring with Low Friction |

1* For 250MPa Series

2* For 250MPa and 350MPa Series

3* For Piston Rod ≤100

4* For 250MPa and 350MPa, Piston Rod ≤100

Hydraulic Cylinder Mounting Types

Main Production and Inspection Process

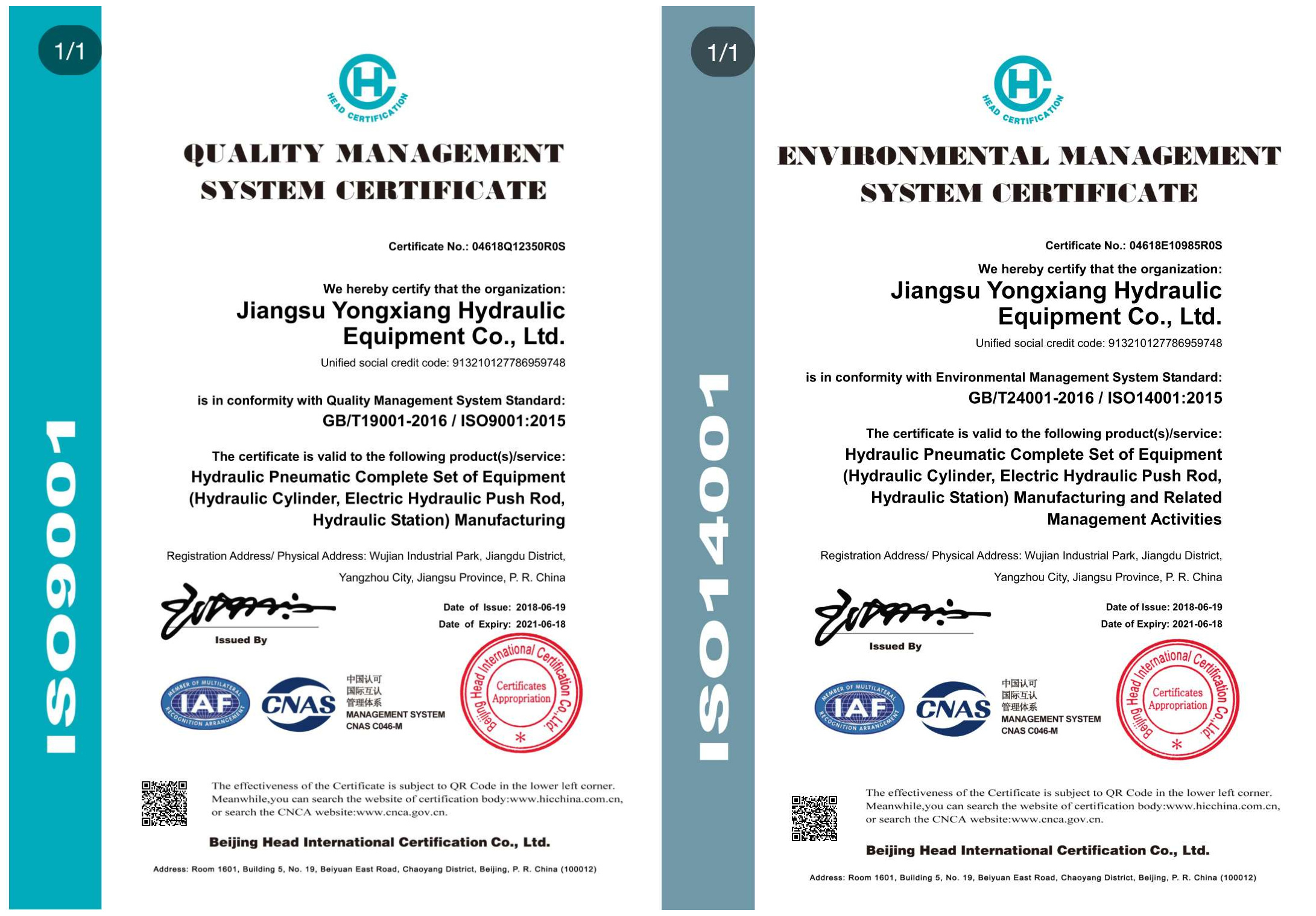

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes a measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection Process:

Inspection Process: | Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes a measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs take inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

| Bore | Rod | Stroke | Work Pressure | Mounting | Work environment |